A wood-burning oven provides a beautiful focal point in an outdoor kitchen. It is also a great stand alone for outdoor cooking and entertaining. Many people building a wood-burning oven have been dreaming about it for years. This page gives an overview of what you need to know when you get serious about building a wood-fired oven.

When planning your project, it is important to understand what goes into a pizza oven. All wood-fired oven projects have these components:

- Footing

- Base

- Functional Oven Appliance

- Veneer

- Venting

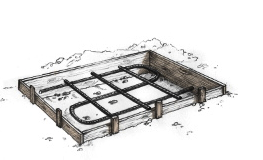

The Footing

If you plan to put your oven on a foundation slab poured at the time your home was built, you are set. If you need to extend your patio or add a footing in your yard, the specifications will vary depending on what your municipality requires. Check with your local governing groups before building. Wood-burning pizza ovens can weigh over 5,000 lbs. We recommend using #4 rebar. In most installations, the oven foundation should have a 12-18” footing with the center at least 6” deep.

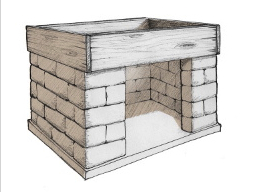

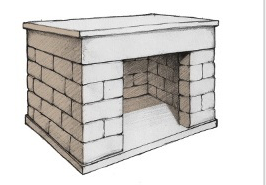

The Base

Most residential installations go for a basic concrete block base with wood storage below the oven. The base can extend on either side to accommodate other cooking appliances, additional countertops, and add base cabinetry for storage. The concrete block base must be reinforced to support the weight of a wood-burning oven.

To keep wood accessible (and minimize the space available for critters) we recommend sectioning the oven base. The base foot-print is about 6′ square for most residential ovens. We partition off a section toward the front to provide storage for two stacks of wood.

The Insulated Crossover Slab

A correctly insulated and formed crossover slab is critical. The crossover slab becomes the base of the oven hearth, and it is an important thermal break. The crossover slab can either limit or augment the oven’s thermal mass. The crossover slab must be absolutely level in every direction before we build the oven vault (or assemble a refractory kit).

We prefer to do the insulated crossover slab ourselves, even if another contractor (or the homeowner) has built the base. In addition to needing a perfectly level surface, we use a proprietary layering of insulating and non-insulating material to control the final thermal mass of the oven. The right thermal mass may vary depending on how you plan to use the oven.

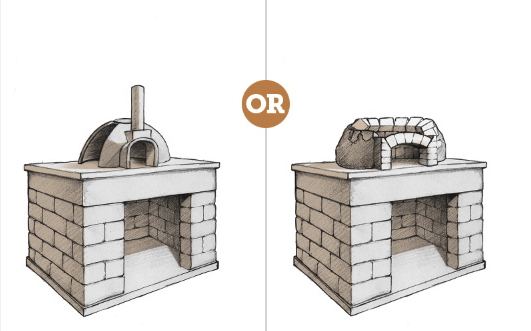

The Oven Appliance

For the oven itself, choose either a handcrafted wood-burning oven or a refractory oven kit. See our Texas Oven and Do-it-yourself-kits pages for more information on the right oven for you.

Insulation and Weatherproofing

Once the oven core is constructed, it is wrapped in a ceramic blanket and a rough coat of high-heat mortar. The construction and insulation on our handcrafted wood-fired ovens provide days of cooking from a single burn. A well-insulated oven is comfortable to touch on the outside even when the internal temperature is over 1,000 degrees. The insulated oven core can be weatherproofed in either a dome or box shape.

Dome – a visible dome is the classic shape. Once the oven has a rough coat of stucco to protect the insulating blanket, it is cured before finishing.

Box – the dome is enclosed in a block box. This option works when the oven is enclosed in a wall or finished with a gabled roof. The oven core is enclosed in a small concrete block box to protect the insulating blanket and is cured before finishing.

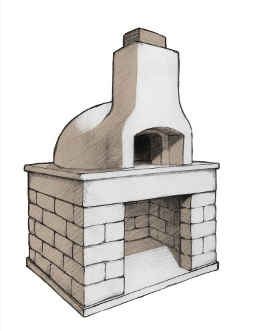

Finish-out Masonry

From the classic exposed dome oven with a rough stone façade to a sleek modern stucco box with steel trim, your functional oven appliance can be finished-out to suit your taste and match your home.

We are happy to take an oven project from the ground all the way to our First-fire™ service where we bring food and get our customers up to speed on using their ovens. On many projects, we come in as the oven experts and build the base, crossover-slab, and functional oven appliance. At that point we transition the oven over to another crew to complete the finish-out. Either way, a beautiful finish-out makes a wood-burning oven the centerpiece of an outdoor space.

Venting

Venting styles and costs vary depending on the oven’s position. When planning the project, consider venting first, especially if the oven will be under a cover. Ideally you want to put in the oven and venting before the framers are on site.